welcome the customers all over the world.

welcome the customers all over the world.

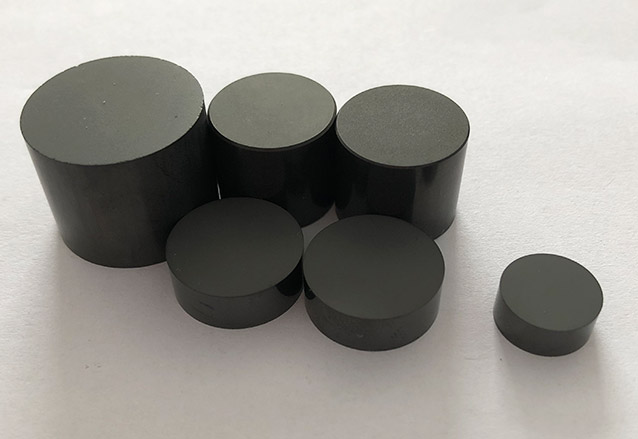

PDC (Polycrystalline Diamond )cutter is a super hard synthesis of diamond layer and a tungsten carbide substrate.Combining the properties of both super hardness and abrasion resistance of diamond with outstanding strength and toughness of of tungsten carbide,PDC has been widely used in mechanical industry,oil well drilling,geological prospecting drilling and coal mining.

PDC (Polycrystalline Diamond )cutter is a super hard synthesis of diamond layer and a tungsten carbide substrate.Combining the properties of both super hardness and abrasion resistance of diamond with outstanding strength and toughness of of tungsten carbide,PDC has been widely used in mechanical industry,oil well drilling,geological prospecting drilling and coal mining.

Application

Oil and gas drilling,downhole tools

| Size | Diameter(mm) | Height(mm) | PCD Thickness(mm) | PCD Layer shape |

| 1308 | 13.44 | 8 | 1.8-2.0 | Flat |

| 1313 | 13.44 | 13.2 | 1.8-2.0-2.2 | Flat,3D |

| 1613 | 16 | 13.2 | 2.0-2.2 | Flat,3D |

| 1616 | 16 | 16.3 | 2.0-2.2 | Flat,3D |

| 1913 | 19.05 | 13.2 | 2.0-2.2 | Flat,3D |

| 1916 | 19.05 | 16.3 | 2.0-2.2 | Flat,3D |

| 1919 | 19.05 | 19 | 2.0-2.2 | Flat,3D |

We supply different series PDC cutters to meet your different drilling requirement.

For main cutting of PDC Bits and PDC Hole Opener in oil and gas drilling complex formation.

Feature:

With Excellent Impact Resistance/High Wear Resistance/High Self-sharpness/High Strength/High Hardness/High Stability, this ensures achieve high Rates of Penetration (ROP) with longer tool life, deeper drilling depth.

For back cones,and gauge protection parts of PDC Bits/PDC Hole Opener/ Stabilizers/ Downhole Tools in oil and gas drilling,and for drive bearing.

Feature:

Oil & Gas industry demands high speed, durability and toughness, PDC cutters will achieve all this in the downhole application.